Redefining the dawn Feed Run (and Giving You Your Life Back)

If you’ve spent any time in a tractor seat on a scorching hot afternoon, you know that "grit" is often just a fancy word for "I’m exhausted and my back hurts." At DOM Distribution, we’ve always been about that grit—the hard work that builds Australian farms. But we also believe that work should be smart. If you could have a farmhand that never sleeps, never complains about the heat or cold, and hits every ration with mathematical precision, why wouldn’t you?

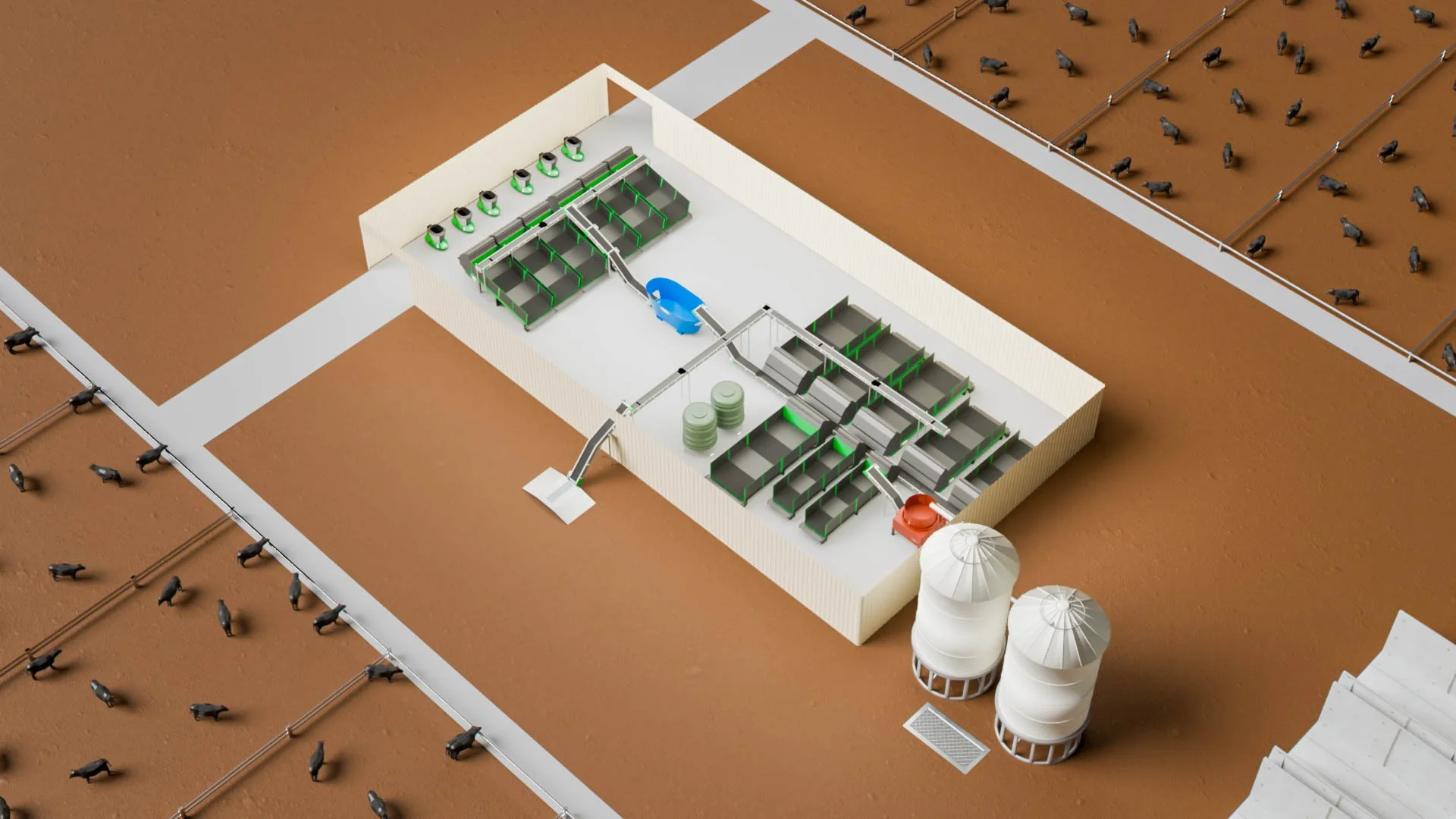

That’s where Greenline with the Shuttle Eco comes in. As the centrepiece of our first major automation installs across Australia—including the game-changing setup at Strathdale Wagyu—this isn’t just a fancy toy. It’s a shift in how we think about livestock performance.

Why "Good Enough" Feeding Isn't Good Enough Anymore

Traditional feeding is a game of averages. You mix a big load, drop it once or twice a day, and hope for the best. But cows are like teenagers at a buffet—they sort through for the "good stuff" (the concentrates) and leave the fibre behind. This kind of feeding creates rumen pH rollercoasters that kill your efficiency.

The Greenline Shuttle Eco, powered by Wasserbauer, flips the script. It operates on the "little and often" principle. By delivering fresh, perfectly mixed rations up to 12 times a day, it mimics natural grazing.

The result? A stable rumen, zero sorting, and calmer cattle.

Precision That’s "Powered by Wasserbauer"

While Greenline is our Australian-born automation brand, we’ve partnered with the best in the world to make it happen. The Shuttle Eco is powered by Wasserbauer’s decades of Austrian engineering excellence.

This isn't just about sticking a battery on a mixer. It’s about:

Intelligent Navigation: No complicated GPS. The Shuttle follows magnets embedded 5mm into the floor. It’s simple, it’s robust, and it works every single time.

The Power-Mix System: The 2.2 m³ hopper uses a high-performance auger that ensures every mouthful is identical. No "yesterday’s leftovers" mixed in.

The "Butler" Function: Not only does it feed, but it also pushes feed back to the bunk on its return leg. It’s like having a butler who also cleans up after the party.

Now Proven in Australia

We know there’s a healthy scepticism in the bush. "Will it handle our heat?" "What happens when the dust gets in it?" We’ve put these units through their paces in our first wave of installs. From high-value Wagyu operations on the Southern Downs to intensive dairy setups, the feedback has been unanimous: It just works.

Our GM, Luke Muller, recently walked through one of our first fully integrated "Feed Kitchens." The system takes raw commodities, batches them via the MyPort storage system, and loads the Shuttle Eco automatically. Your job? Monitor the app over a coffee.

The Bottom Line: Does It Pay?

We aren’t here to oversell. Automation is a big step, but the math is hard to ignore:

Labour Savings: You’re not just saving hours; you’re eliminating the need for a dedicated feeding position.

Fuel and Maintenance: The Shuttle is 100% electric. It charges at its dock and uses about 20 kWh a day. Compare that to the diesel bill for your 200hp tractor and a mixer wagon.

Animal Health: Increased Dry Matter Intake (DMI) and better rumen health mean more milk in the vat or more kilos on the scale.

Getting Your Nights Back

At the end of the day, DOM Distribution is a family business. We know that "Grit and Growth" is about building something that lasts. The Greenline Shuttle Eco, powered by Wasserbauer, is about ensuring that the next generation of Australian farmers spends more time managing their business and less time fighting with a gearbox at all hours. Start the ball rolling on how the Eco Shuttle can transform your livestock feeding today.

System Walk Through: Greenline Automated Livestock Feeding

This video provides a first-hand look at one of the first Greenline Shuttle Eco installations in Australia, showing how the "Feed Kitchen" and robotic shuttles work together to automate the entire feeding process.